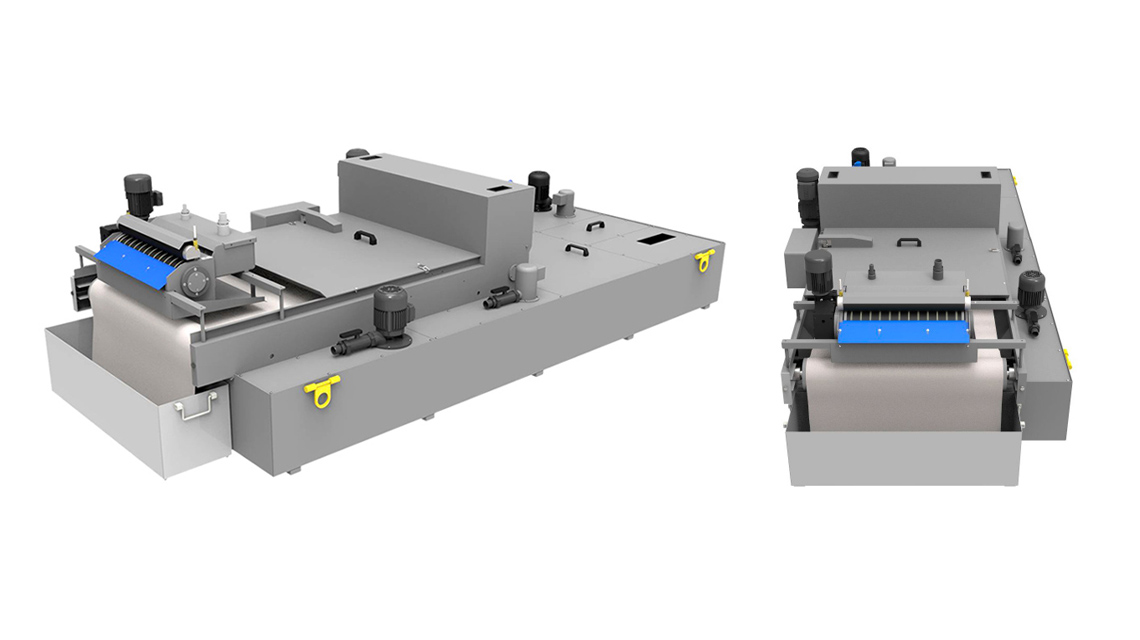

Compact Band Filtretion System

- Compact band filters well suited for high flow rate and dirt content.

- specially designed for space efficiency and require only 20% of the space as compared to other conventional compact band filters Clarity level : 75 microns to 3 microns.

- By using different grades of filter papers, the desired filtration effects can be achieved.

- The optimum sealing between honeycomb mesh, drum assembly and filter paper completely eliminates any fear of contamination.

| MODEL | CAPACITY | Inlet Height | FILTER PAPER WIDTH | DRUM DIAMETER | TANK CAPACITY |

| CB-DSLT | 60 LPM | 445 MM | 600 MM | 490 MM | 200 LTRS |

| CB-DSLT | 100 LPM | 445 MM | 700 MM | 490 MM | 300 LTRS |

| CB-DSLT | 150 LPM | 445 MM | 800 MM | 490 MM | 450 LTRS |

| CB-DSLT | 200 LPM | 570 MM | 800 MM | 640 MM | 600 LTRS |

| CB-DSLT | 300 LPM | 570 MM | 1000 MM | 640 MM | 900LTRS |

| CB-DSLT | 500 LPM | 720 MM | 1000 MM | 840 MM | 1500 LTRS |

| CB-DSLT | 1000 LPM | 770 MM | 1500 MM | 940 MM | 2000 LTRS |

| CB-DSLT | 2000 LPM | 970 MM | 1500 MM | 1340 MM | 3000 LTRS |

Paper Band Filtrestion System

This entire unit is fixed on a coolant tank with a pump to supply coolant to the machine. The filtering paper is spread over an endless steel mesh conveyor which is connected to gear motor. This uniquely designed conveyor prevents overflowing of liquid and the full width of the filtering paper is used. The movement of the filter paper is controlled by a float switch which actuates the gear motor.

This is a Perfect solution for cleaning of coolant emulsions and cutting oil.

Application: Grinding, Drilling, Honing, Polishing and Washing.

Advantages :

- Highly efficient way of filtration guarantees fine finish, dimensional accuracy, increased tool life.

- Keeps your machine clean and reduces costly machine down time for periodical cleaning.

- Avoids bacterial growth and wastage of expensive coolants.

- Since the complete filtration system is automatic, No manual attention is needed.

- Where heavy stock removal increases the temperature of the coolant, this system of filtration due to sufficient exposure to air helps to control the same.

| MODEL | CAPACITY | CUTTING OIL | EMULSION | L | LT | W | WP | TANK CAPACITY |

| PB-DSLT | 50 LPM | 35LPM | 50 | 1100 | 1300 | 550 | 450 | 150 LTRS |

| PB-DSLT | 65 LPM | 45 LPM | 65 | 1200 | 1400 | 800 | 700 | 200 LTRS |

| PB-DSLT | 100 LPM | 65 LPM | 100 | 1600 | 1800 | 800 | 700 | 300 LTRS |

| PB-DSLT | 150 LPM | 100 LPM | 150 | 1600 | 1800 | 1000 | 900 | 375 LTRS |

| PB-DSLT | 200 LPM | 130 LPM | 200 | 2000 | 2200 | 1000 | 900 | 440 LTRS |

| PB-DSLT | 300 LPM | 200 LPM | 300 | 2300 | 2500 | 1000 | 900 | 575 LTRS |

| PB-DSLT | 400 LPM | 250 LPM | 400 | 200 | 2200 | 1170 | 1370 | 750 LTRS |

A B O U T U S

DN Technologies Pvt. Ltd.

Because when a visitor first lands on your website, you’re a stranger to them. They have to get to know you in order to want to read your blog posts, subscribe to your email newsletter, or buy what you’re selling.

From repairs to installations, our services shine. Reliable solutions, every single time.

Filtration Syestem And Magnetic Separator

Chip Conveyor And Tilting Type Chip Trolley

Air Dryer DeHumidifier

Stabilizer, Transformer, UPS

Sump Sucker , Coolant Management

Washing & Cleaning Machine

All Type CNC VMC Machine Peripheral & Maintenance

Communications

Gat no 396 , plot no 37, Dehu Alandi road , Near canbay Chowk, Talawade, Pune 411062 Maharashtra

+91 7588351631

Monday to Sunday 10am — 8:30pm

dntechnologies.in

dnsalestech@gmail.com

Copyright © 2024 TermsFeed®.

All rights are reserved by DNTechnologies.in.