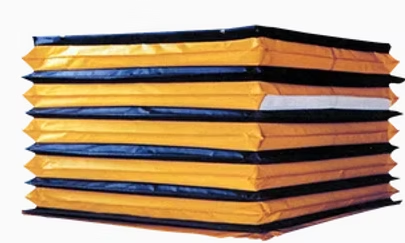

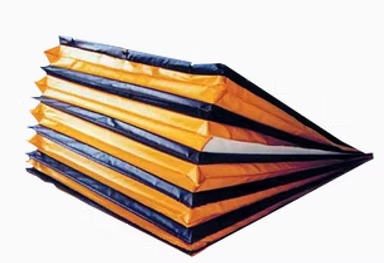

LIFT TABLE BELLOWS

OPERATOR SAFETY & MECHANICAL PROTECTION

Many safety conscious companies are insisting on lift table bellows in order to stay up to date with today’s safety standards.

By providing a physical barrier, our lift table bellow covers help prevent injury due to hands, clothing or feet being accidentally caught in the lift table’s pinch points. Protecting the lifting mechanism from contaminants such as dust, dirt, water and foreign objects, minimizes downtime and maintenance costs and extends the life of the unit.

DESIGN FEATURES

SINGLE OR MULTIPLE SIDED

one, two, three and four sided lift table skirts are available for Lift, Tilt, and Lift and Tilt tables

PREMIUM QUALITY VINYL COATED POLYESTER

the 3” wide material is welded together at each corner before sewing to ensure perfect 90 degree corners and uniformity

MESH BREATHING FABRIC

on four-sided units, a mesh breathing fabric is sewn into opposite sides on a convolution near the top, to allow for the influx & expulsion of air as the enclosure cycles up & down

EXTENSION STRAPS

eases pressure on the stitching by creating uniform extension at each convolution

GALVANIZED MOUNTING FLATBAR

flatbar is included, if required, for installation into collars which can be located two ways:

1. Sewn to the inside dimension of the enclosure in which case the body will hang outside the outside dimension of the table.

2. Sewn to the outside dimension of the enclosure in which case the body will hang inside the outside dimension of the table.

OPTIONS

MAINTENANCE STRAPS

to hold the enclosure up against the underside of the table for ease of access when performing maintenance.

ZIPPERS

for retrofits where the lift table skirt may not be easily slipped over the table

HOOK & LOOP MOUNTING

instead of flatbar

HI-TEMPERATURE FABRIC

specialty fabrics are in stock for unique applications

RESTRICTED SPACE & LOW RETRACTION

although 3” convolution width is standard, almost any width can be fabricated to satisfy special situations.

From repairs to installations, our services shine. Reliable solutions, every single time.

Filtration Syestem And Magnetic Separator

Chip Conveyor And Tilting Type Chip Trolley

Air Dryer DeHumidifier

Stabilizer, Transformer, UPS

Sump Sucker , Coolant Management

Washing & Cleaning Machine

All Type CNC VMC Machine Peripheral & Maintenance